OUR LOCATION:

Birmingham Road, Pathlow

Stratford-Upon-Avon, CV37 0EP

Rear Hub Conversion kit from Dangerous Taper Halfshafts & Internally Tapered hubs to Spline drive for DB2 to MkIII , Jaguar solid axles, anything with a Solid Salisbury axle

- Our Price Includes VAT @: 20%

- Stock: another 5 kits on their way, sold 1st 5 kits within 3 days

- Actual Price: £2,940.00

Description

Rear Hub Conversion kit (Normally used for Racing & Rallying but can be used in road cars) converts Dangerous Taper Halfshafts & Internally Tapered hubs to easy to use & safer Spline Drive & Semi Floating Hub Bearings (Like a Midget / Sprite) fit Aston DB2 to MkIII, Jaguar MkII & ALL Jaguar solid axle cars, Now available for Jensen & Bristol with 4HA axles, in fact anything with a Salisbury 3HA or 4HA axle including Escorts (upon request although they already have their cheap Atlas GP4 kits) & Manta's, please enquire

Kit prices start at £2450 + VAT per axle set for the DB2 to MkIII models (5 kits in stock to start with - all sold on the 1st day we had them in November 2019, expecting 5 more kits July/August 2021), this compares well with std hubs, std halfshafts & keys, std bearings, std hub inner & outer seals, std seal housings, etc + special tools & lots of labour to assemble them.

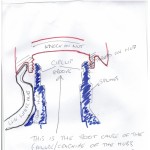

Due to positioning of everything the brake drum & backplate is in a slightly different place, because of this & the fact that it is a racing / rallying conversion you should be using 72 spoke wheels which are stronger that the original DB2 to DB2/4 MkII 60 spoke wheels.

Comprehensive 30 part Kit contents:

2 x Special HD hubs to suit application (as 1st photo) , 1 x LH & 1 x RH, DB2 to MkIII 42mm splined type initially then DB5 & 6 kits then 52mm Splined Jaguar type & 5 stud Jaguar type available upon request.

2 x Special halfshafts made from M300 (for 19 & 18 Spline diffs ) to suit various applications, at present for all Feltham models & some Jaguar models

2 x Special Abutment Collars, fits on halfshaft & buts up to inside of bearing

2 x Special Hub outer bearing housings.

2 x Special Hub seals for above housing

2 x Outer hub bearing axle to brake backplate adaptor housings to suit application, drum brake 3HA type initially, 4HA drum brake type are next then Jaguar Disc Brake type to suit the MK2 & XK unless we have orders for them straight away, we will make drum braked XK & Mk1 components on request and a STD part supplied.

2 x O rings for above where they fit into the original bearing housing on the axle casing.

2 x Hub outer double row heavy duty ball bearings - easily available type, packed with very HT grease.

2 x Special nuts instead of Castellated nuts

2 x washers for above

12 x new Hub Bearing housing bolts, washers, etc.

2 x blanking plugs for original grease nipples

1 x drilling jig - on loan to purchaser

Instructions for assembly

Optional Items

1 x adaptor for press / puller to remove hub from bearing, not expensive

1 x slug for hub internal dia to use with above

1 x splined hub puller / slide hammer kit or just slide hammer if you already have the hub puller (not Churchill type hub puller)

1 x diff backplate gasket

1 x set Crown Wheel bolts, either drilled for lockwire (don't use the locktabs) & loctite patched or serrated flange (Durloc type)

2 x Alloy rear Brake backplates - similar to the Works DB2s, fits DB2 to DB MkIII, reduces unsprung weight / overall weight, machined from solid & anodised black

2 x Alloy brake adjuster housings for DB2 to MkIIIs, reduces unsprung weight / overall weight, machined from casting & anodised black

Following on from my article, the next set of kits will be in stock shortly,

please read my article if you haven't already, here

Salisbury 3HA & 4HA axles & all modern derivatives, used for racing & rallying.

Advantages with Our Redesigned Rear Hub & Halfshaft Kit.

These replacement halfshaft kits don't require complex shimming of the taper roller bearing / halfshaft end float & several special tools, including a hub puller, halfshaft puller, DTI / Clock gauge & some kind of supporting arrangement to hold the clock gauge, they don't use a taper roller bearing, halfshaft bearing strengthening plate, outer hub seal carrier & seal or any paper gaskets on the axle ends.

The halfshafts are generally stronger without the stress causing keyway or the problem causing taper fitting arrangement between the hub & halfshaft

Better rear brakes due to lack of movement / flex of halfshafts on the drum / disc arrangement.

Our halfshaft bearings can be easily be replaced without special tools in about 40 minutes with the correct tools, the halfshafts can be replaced in about 15 minutes (at the side of the road or in the paddock,) if a halfshaft does break it will only break between the hub bearing mounted on the end of the axle tube & the diff unit, the car will then roll to a stop.

Because the weight of the car via the hub & wheel assembly are supported by a large easily obtainable bearing mounted securely in a bolted / mounted housing on the end of the axle and the halfshaft only being used to transmit drive, higher cornering loads are then fed into the new hub unit not the halfshaft, of course this design of halfshaft also lengthens the life of the bearing & diff unit, the racing / competition tyres may also last longer but maybe not.

Better design of rear hub which is a failure point on a DB2 series Feltham car, possibly exceeding 'Andron' (an Aston Specialist designed part) style rear hub strength (all new hubs made since the early 1990's) as the dont vary in inner diameter.

Lighter Weight than STD components

Gets rid of halfshaft spacer as (should) no longer be needed but the diff cross pin is still needed.

It fits our lightweight hybrid axles

One disadvantage

The axle can't be bent to give negative camber unless you increase the clearance between the sun wheels & the diff casing, if you do bend the axle casing you are on your own